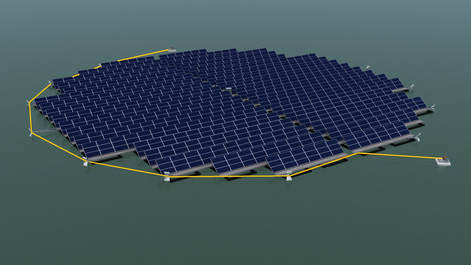

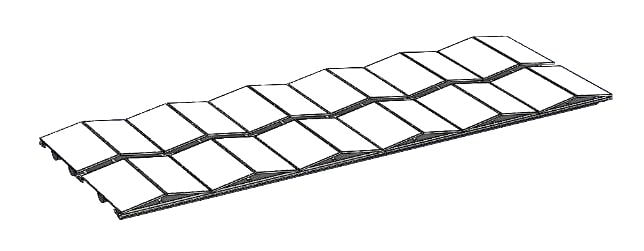

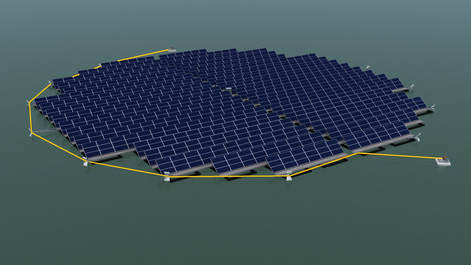

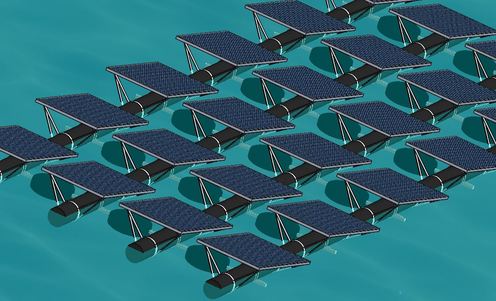

RaftsRafts are the basic constituents of our floating plants-. Their main charctersitics are: |

|

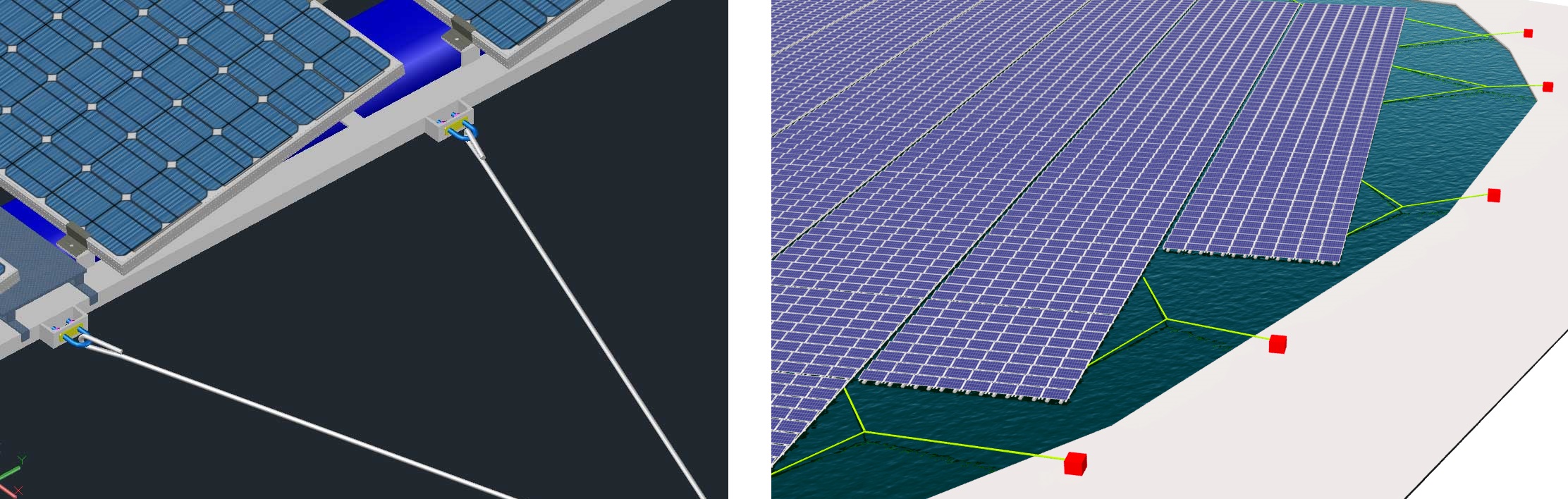

Modularity: the structure is modular. Raft components are pipes and beam of galvanized steel and can be easily assembled in a very short time. PV modules are installed and connected working on the land.

Flexibility: the structure can be modified in order to implement cooling systems, and tracking.

Robustness: the floating platform is quite heavy. In its steel-HDPE version a 1 MWp platform has a tonnage of more than 150 tons and is insensitive to wind gust and storm. |

|

Safety: several elements contribute to the safety of the structure:

- walkability which allows operators to move safely on the platform for maintenance or control problems and which is very good due to the large buoyancy of our raft project.

- Simplicity of launching: The raft can be assembled on a slide and slipped by thrust into water.

|

|

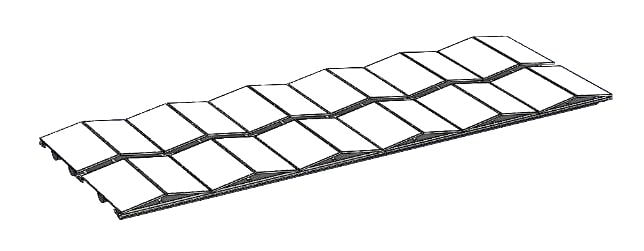

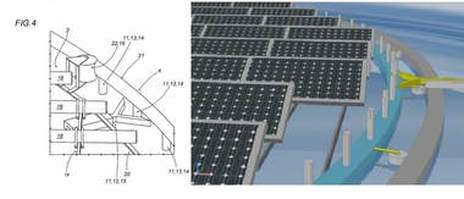

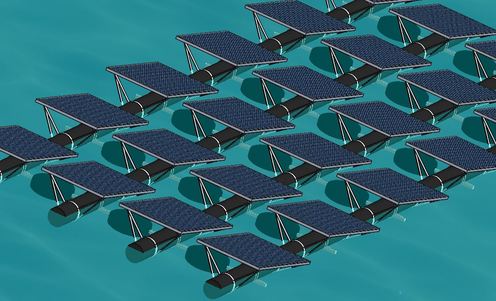

Solution with gable for improoving packing density. This solution is particularly interesting for low latitudes (below 25°) since in this case the very small loss in energy harvesting is largely compensated by the lower cost and compactness of the system. |

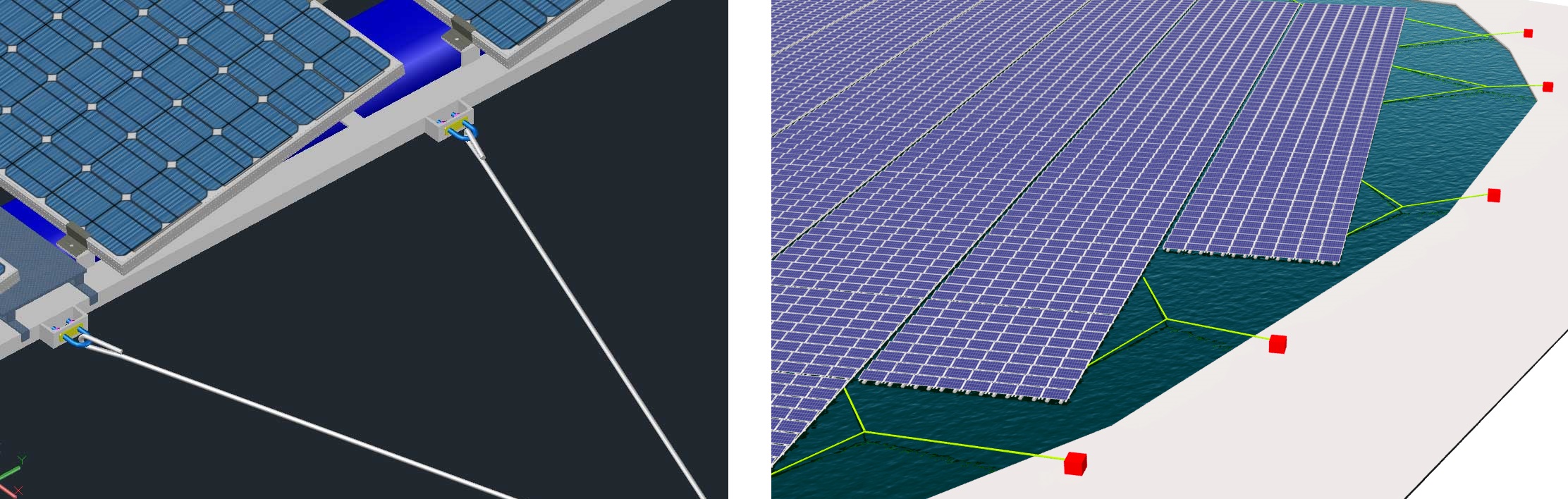

Mooring

|

Standard onshore mooring

|

The mooring of a floating PV plant changes if the plant is fixed or with tracking and furthermore it depends on the location morphology. A detailed project requests the knowledge of several aspects of the basin. Normally the bottom of the basin is muddy. In this case we need a few mooring sinkers and the total cost is about 2-3% of the full plant cost.

|

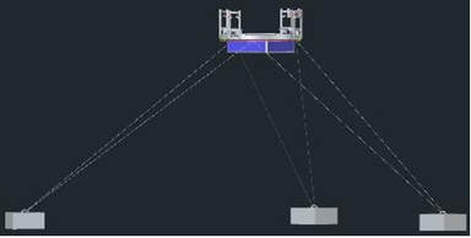

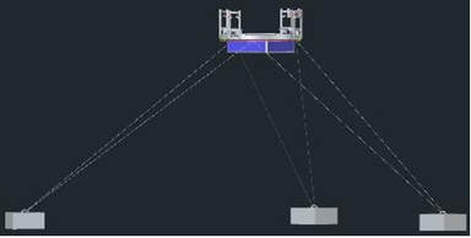

Mooring for a Plant with tracking

|

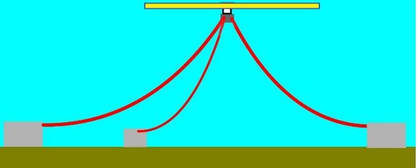

For a plant with tracking three sinkers positioned at the corner of a triangle (approximately equilateral) are connected with long chains to a central nozzle which is the pivot of the floating platform. The three chains are connected to a central point lying one meter below the water surface and attached with a one meter long chain to the centre of the platform. |

|

As you can imagine the points of mooring are the most important aspect regarding to safety. This is how we do it.

We strongly advise to compare this with the solutions chosen by our competitors. |

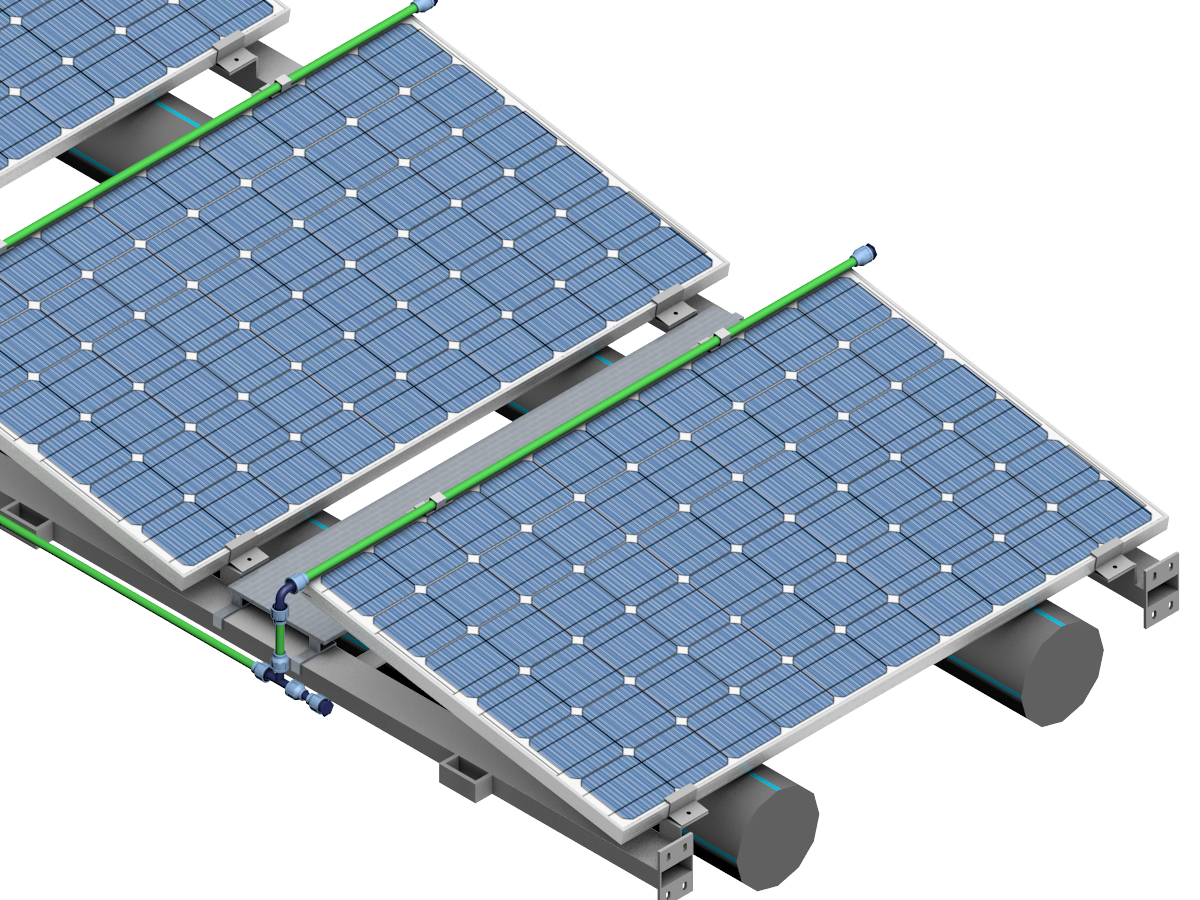

Cooling |

|

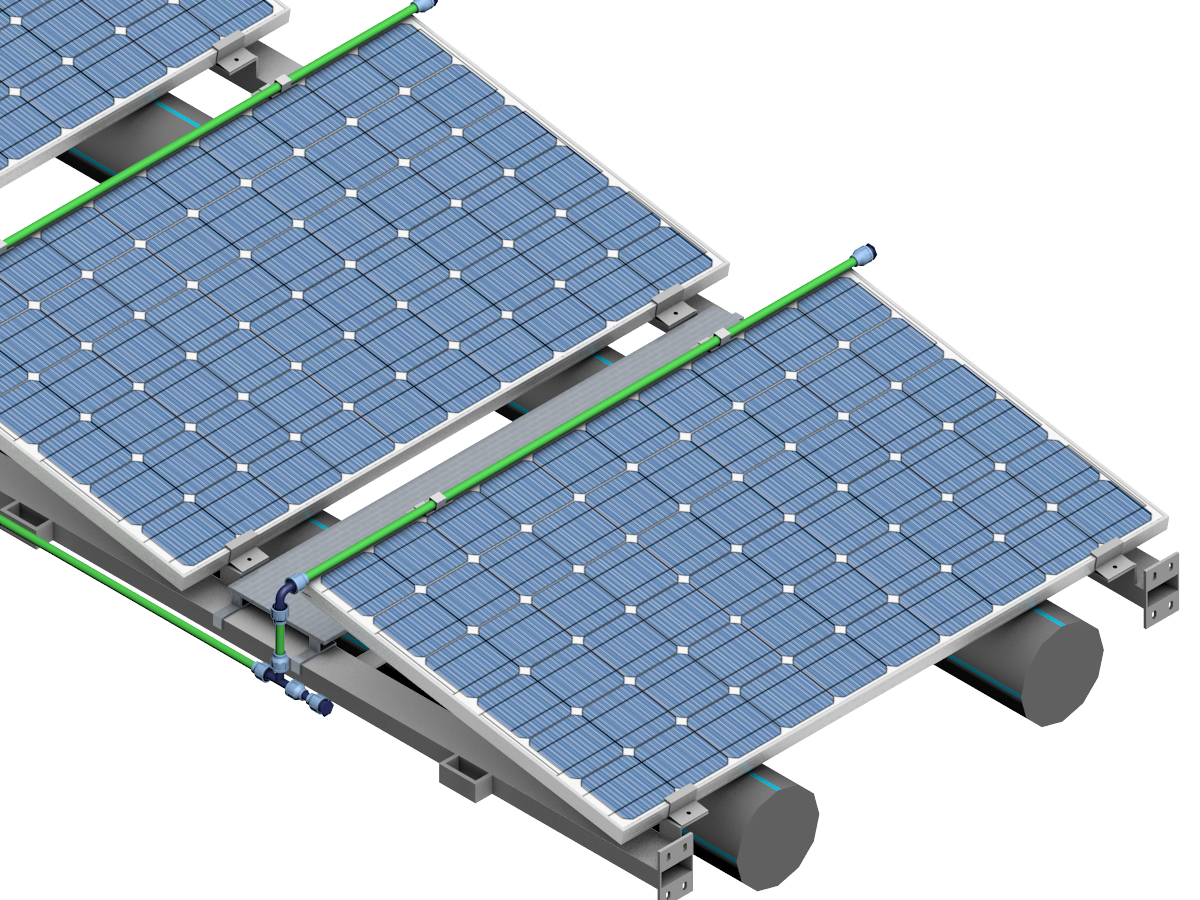

Water Veil Cooling system is an irrigation system constituted by:

- A set of polyethylene pipes positioned on top of each panel. This ad hoc system can be substituted by drip irrigation pipes.

- A control system to switch on the pump when the panel temperature exceeds a fixed threshold (30 °C is a typical value).

- A low pressure water pump.

A simpler alternative cosists in the use of sprinklers. The problem of shadow due to the water jet can be limited by an intermittent use of the sprinklers during the sunny hours.

|

TrackingTracking systems allow a better capture of solar radiation and increase the yearly energy harvesting.

The full platform floating in water can easily turn around its vertical axis without mechanical efforts. We have studied sevral tracking systems

|

|

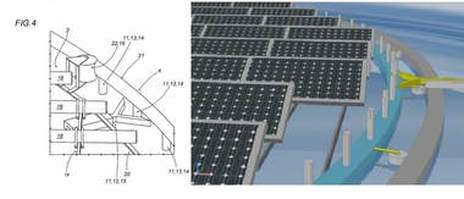

System of tracking with confinment. The platform is put inside a reference frame and turns thanks to a rolling wheel. Patented

|

|

Sistem of tracking with a mooring in the platform center (eventually a fix pole) and a system of ropes pulled by whinch. Patented

|

|

System with a submerged support moored in a triangular way. The platform rotates respect to the submerged support. Patented

|

|

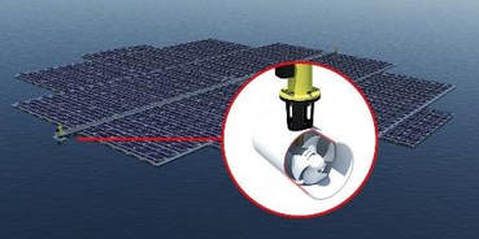

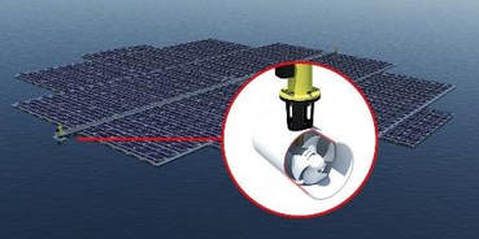

System without confinement and with central mooring. The tracking is generated by bw thrusters which are controled by a software coupled to a solar sensor. This system has been implemented both in Pisa and in Suvereto plants.

Look at this video |

Reflectors

|

|

The use of reflectors allows to increase the energy harvesting and to reduce the PV panel surface.

In this case tracking is cumpulosry and this is one of the reason why systems with reflectirs are not popular. Due to simplicity of tracking for a floating platform and the possibility to cool the panels, avoiding in this way the thermal drift, this technique is very advantageous and has been tested succesfully in Colignola plant (Pisa).

|

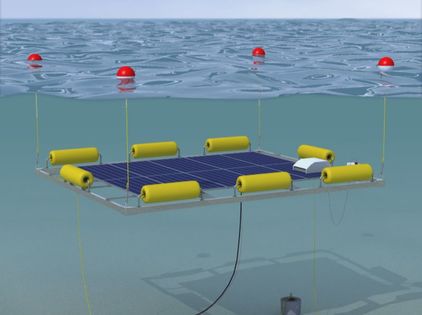

Submerged Photovltaic Solar Panel (SP2)

|

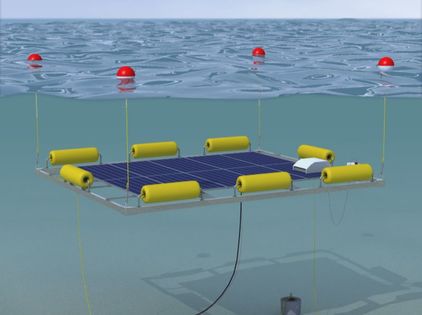

|

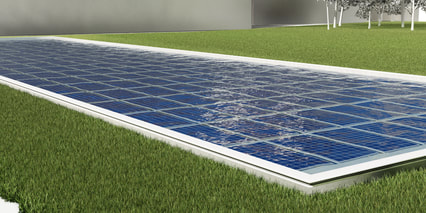

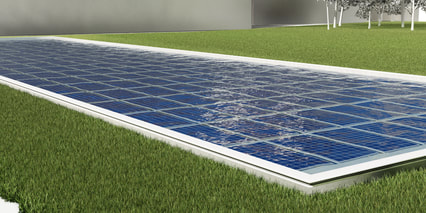

The photovoltaic materials, in particular silicon and CdTe, have a negative thermal drift, i.e. they lose efficiency when the temperature increases. Water keeps the temperature of the panel constant thus avoiding the thermal drift, and at the same time the panel doesn’t lose efficiency. This allows us to realize a gain in efficiency of approximately 20% in the summer time.

The system is not visible from the surface. In figure at left is shown in open basins with buoys which score its presence

In figures below it is totally invisible. This is a project done for Venitian Villas who was awared of the first price from Venise region in 2016. |

Project of a SP2 for Villa Venier (near Padova). Venetian region awarded the first prize this porject in 2016

|

Villa Pisani: its pool is suitable for SP2

|

Off-Shore

|

|

Recently our researching activities are expanding into the off-shore where we propose new solution.

|

|